To offer better packaging, new trends and technologies are often looked at by companies and organizations. As packaging serves as protection and preservation, and marketing, it’s a fairly important element of any brand or product. In improving overall marketability or offering advantages beyond existing cardboard, technology trends in packaging are something to be aware of.

Here are the nine technology trends in packaging:

Trend #1: Smart packaging

There are lots of ways to bring tech into packaging. Smart packaging includes QR codes, smart labels, RFID, NFC chips, and near-field communication technology. These packaging additions increase security and connectivity, engaging customers with product content, discount codes, video tutorials, etc.

You can redirect customers to branding online, utilizing QR codes to redirect them to video materials and websites. It’s a win-win for both security and marketing.

Trend #2: Custom packaging

The appearance of packaging is more important than ever, regardless of whether a product’s displayed in a retailer or purchased online and sent by courier. Custom packaging is marketing 101. Boost your brand with eye-catching colours, a unique shape, digital prints, and more.

Whether custom tape or adding other identifiers to your packaging, you can turn an ordinary form of packaging into something extraordinary. Thankfully, due to the lowered cost of packaging manufacturing technologies, there are lots of custom packaging companies available to help.

Trend #3: Affordable digital printing

When you print directly on the packaging, this comes with a major cost. Digital printing, however, doesn’t use traditional techniques and costs a lot less money. This is another route to custom packaging that capitalizes on fast-advancing technology. You can print all sorts of data, from barcodes to QR codes.

Printing services must be tailored to the exact label and packaging requirements. If you aren’t sure how to customize your packaging, searching for digital printing may be an easy way to do so without altering your original packaging concept too much.

Trend #4: Active packaging

Active packaging is packaging with contents deliberately meant to enhance the performance of the containment and protection of the product. This is advantageous for food production companies where food waste can create huge losses.

Active packaging increase shelf life for food and beverages and other products, such as pharmaceuticals. The utilization of ethylene absorbers, antimicrobial agents, anti-mould vapour, and moisture regulators are examples.

Trend #5: AI-influenced packaging automation

AI-powered systems are increasing productivity, precision, and quality control in packaging. Automating processes from filling and packing to palletizing has swept the packaging industry, eliminating human errors and maximizing the safe handling of products.

This type of technology moves through fruit and vegetable packaging and helps to trim, pick, and pack fresh produce. This helps reduce waste, better predict shelf life, and reduce overall expenses in certain packaging types of products.

Trend #6: Biodegradable and recyclable materials

New technology trends are seemingly being revealed every month in eco-friendly, biodegradable, and recyclable packaging. Some of the possible options today include the utilization of post-consumer resins, bagasse, hemp, and polylactic acid. What this does in packaging is eliminate the need for plastics.

There are an endless array of options under biodegradable packaging, from starch to cellulose, PHB, PHA, biopolymers, and plant-based packaging made from sugarcane, coconut, hemp, and corn starch.

Trend #7: Nanotechnology

Nanotechnology is being used in highly technical ways, mixing nanoparticles with polymer chains to enhance packaging barriers and enable anti-counterfeiting features. Nanotechnology is of particular interest to the food packaging industry, where nanocoatings minimize the dirt, dust, and stains that can sometimes occur in packaging.

Nanosensors can also monitor the freshness of food and detect even small chemical changes inside the packaging. It’s a developing area of packaging technology with a lot of promise.

Trend #8: Anti-Counterfeit Packaging

Anti-counterfeit packaging is easier than ever to achieve, installing unique security codes that provide retailers with the chance to track product as it goes through the supply chain. This is accomplished by using a combination of QR codes and cloud computing.

This allows you to minimize waste and better understand where issues occur from a company standpoint. A brand can better control customer and supplier satisfaction, verify transaction histories, add product information, etc.

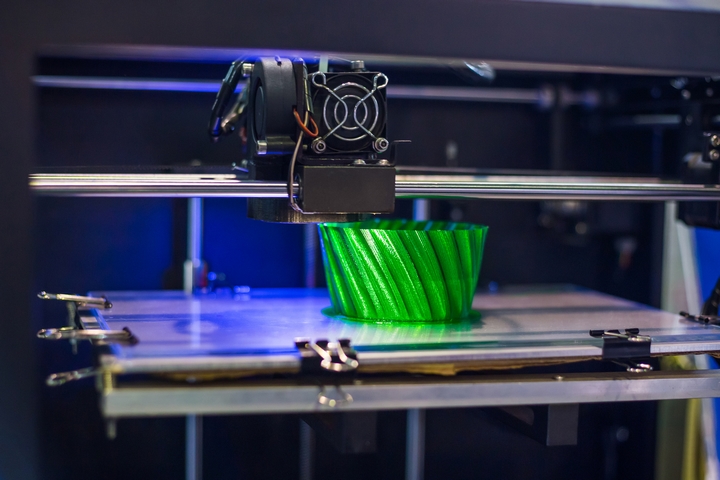

Trend #9: 3D Printing

Without overspending, 3D printing has made it more affordable to construct prototypes and innovative packaging. For brands who want to develop unique, borderline-experimental packaging, you can save time and produce less waste by testing with 3D printing.

This is done utilizing thermoformed plastic packaging materials and can be moulded to the precise specifications you need. 3D printing can dramatically change the affordability of packaging for the medical, automotive, industrial, and electronics industries.