Managing a business takes more than managing the flow of items and services you sell – you also need to keep the equipment that runs your business in tip-top shape at all times. A sudden breakdown of key equipment can lead to massive losses and throw your operations into disarray. This is why it is important to take a proactive approach towards maintenance that includes having a preventative maintenance checklist for equipment. Below are some tips to help improve equipment maintenance in your business.

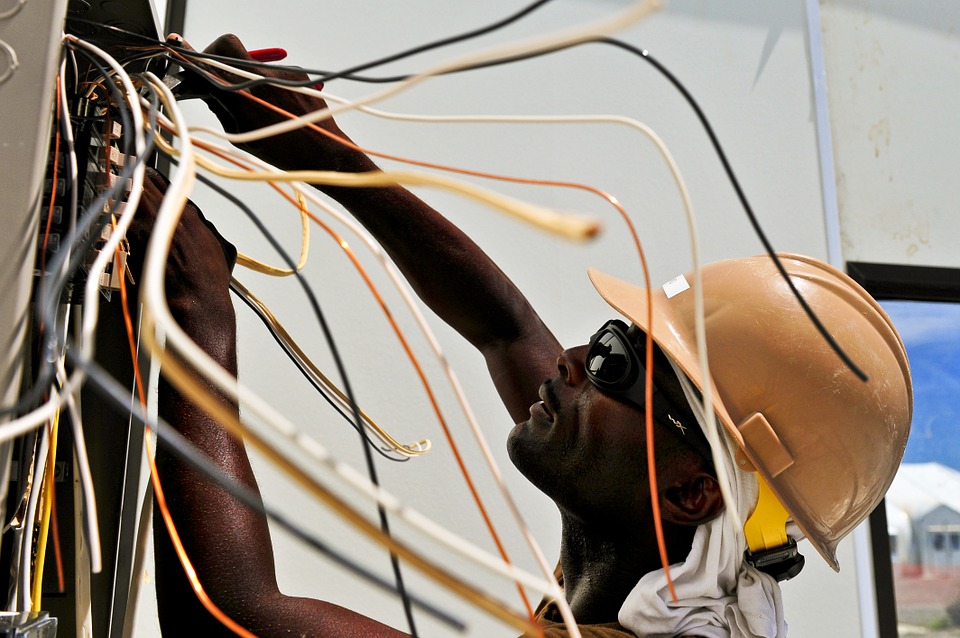

- Cables and Components

Some environments such as food manufacturing can be hostile to mechanical and electrical equipment. Long hours of operation in a place where there are all sorts of chemicals, acids, water, and heat can damage cables and some components of your equipment. For this reason, you might need to go for materials designed for harsh environments when replacing components, wires, and cables.

- Proper Training

It is important to train the equipment operators to prevent malfunctions and unnecessary wear and tear. It might take a lot of time and money to train your employees to set up and operate your equipment, but it will pay off in the long run. You will extend the life of your equipment and improve efficiency.

- Regular Inspections

By conducting inspections of your machinery and equipment every now and then, you are able to detect signs of wear and tear early enough to forestall an unexpected breakdown. This will help prolong the life of the machinery and make your operations more efficient. For example, if you observe that your cables are wearing out, you can replace original equipment with more durable alternatives. This way, the equipment will be able to withstand the environment in which it is being used.

- Hygiene and Cleanliness

If you’re in food processing, then the cleanliness is paramount. Dried on gunk and spills can attract rodents and insects that may damage your equipment and your product. You may also fall afoul of the law. By keeping your equipment clean, you will not only be complying with the law, but also increasing productivity and prolonging the life of your equipment.

- Preventative Maintenance

To keep your equipment running without a hitch, it is important to follow the manufacturers preventative maintenance recommendations. The manufacturer may provide a preventative maintenance checklist for equipment after a set period of time or a certain production level. Follow this to the letter and keep a maintenance log to keep track of every piece of equipment.

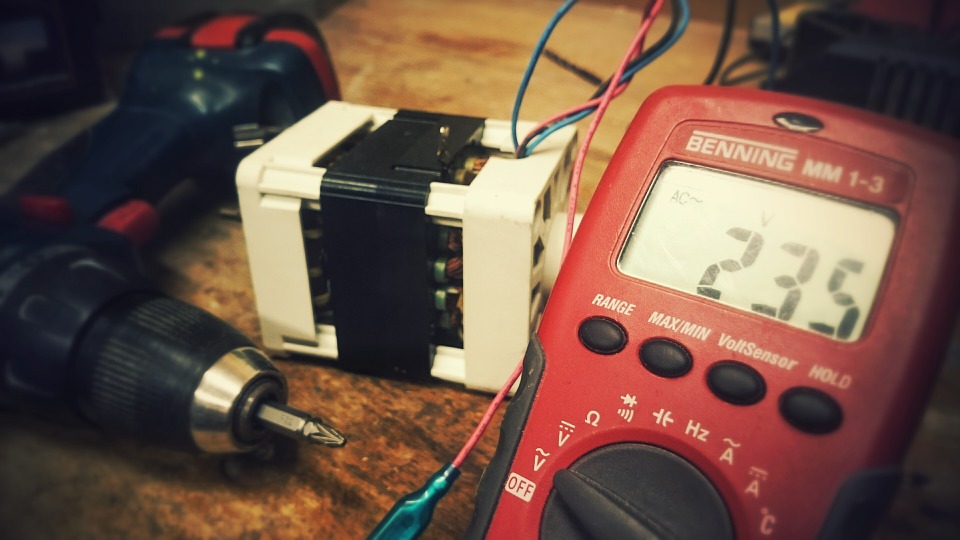

- Calibration

You should calibrate your equipment as part of your preventative maintenance program. This is especially so if you own scales and measuring equipment. You can either do this yourself or outsource to a calibration service provider. If you do it yourself, make sure to adjust your calibration tools and gauges. Failure to calibrate your equipment can lead to poor quality products.

- Monitoring Software

One of the best ways to keep track of your equipment is to invest in proactive maintenance software. This will allow you to take note of subtle changes in metrics such as throughput and productivity. You will receive alerts from the software when it notices that your equipment is not performing as it should. This will give you an opportunity to deal with any issues causing the slump.