Until the end of the twentieth century, the term ‘digital textiles’ was unheard of. Also unheard of was the term ‘wearable’ technology. However, with technological advances in various sectors, it is no longer inconceivable that one can talk of ‘wearing’ technology.

The printing sector has not been left behind in this technological revolution. From 3D to the emerging 4D printing technologies, the future of printing appears set to converge with many other sectors, and potentially disrupt other industries. Below are six predictions for the future of printing technology.

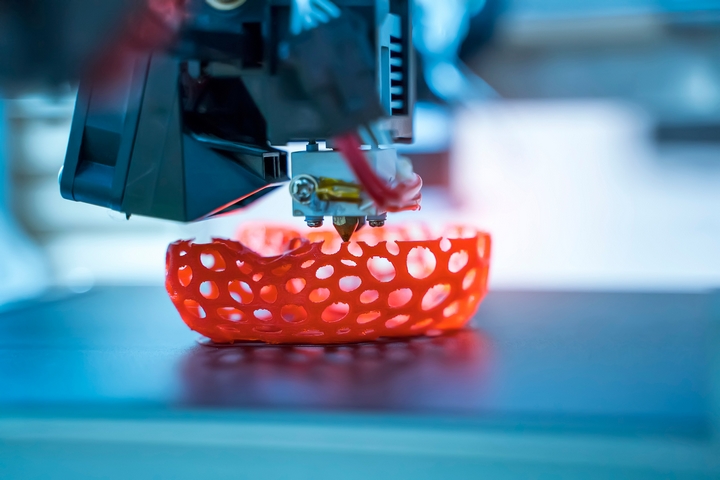

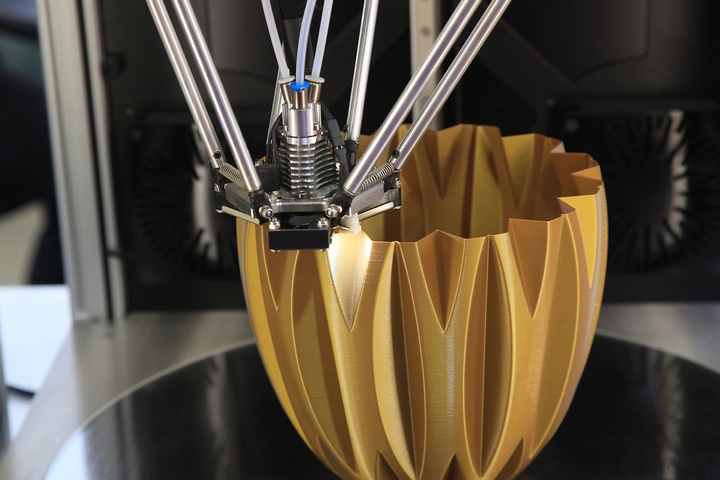

1. 3D printing will become more popular

In the coming days, 3D printing will feature in almost every aspect of life. Already, it is being used in the healthcare sector. It is set to play a major role in the future of printing technology, including the delivery of individualized clinical procedures. 3D printing will feature in prosthetics, joint replacement, surgical implants, and other pre-surgical planning such as the development of anatomical models.

For instance, there are developments in 3D printing of prosthetic appendages and limbs, such as ears using various types of polymers. There have also been rapid developments in hybrid “biosynthetic” structures through the use of bioniks, specialized nozzles for 3D printing stem cells, print heads, and the advanced multi-cartridge capabilities made possible by 3D printing. Besides, although a bit pricey, 3D printed wearables will feature not only in sports but also in the medical sector.

2. Four-dimensional printing (4DP) will take root

4DP features dynamic capabilities encoded on materials either by properties, function or confirmation. These can be varied through the application of nanomaterial, particulates, electronics, chemicals, and advanced designs. Although currently at the innovation stage, the revolutionary 4DP is likely to disrupt industries.

Already, various universities in the world are investing in 4DP research. Publicly owned companies such as HP, Airbus, Stratasys, and Autodesk are also working on 4D printing. While 4D printing will face significant scientific, computer, and engineering hurdles, this technology, once in full flight, will revolutionize almost every sector and disrupt the current balance of industrial innovation.

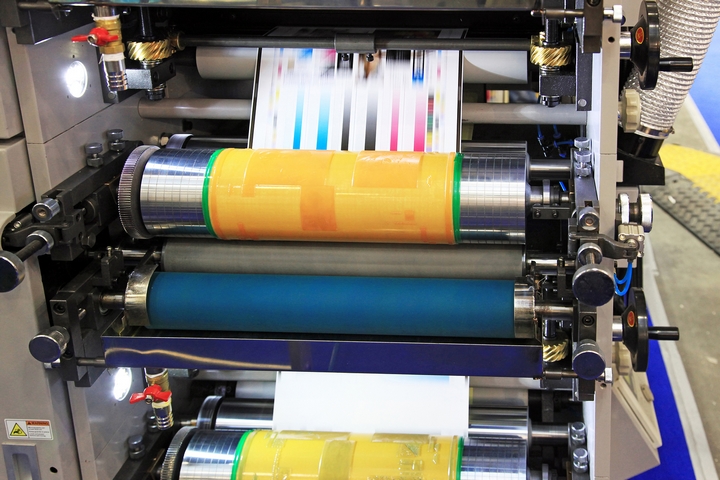

3. Convergence will deepen

As technologies and lifestyles cross over, we are going to see printing technology converge with other industries such as the clothing sector. Already, the wearable technology is gaining traction as it converges with another screen print-based industry, the wearable textile sector. We will see mergers and acquisitions as the convergence of printing technologies and industries take root.

It is reassuring to know that certain classic industrial printing techniques like flexography aren’t going anywhere. In fact, the flexographic industry looks to have consistent demand. There will be a need for flexographic printing, along with flex storage solutions and sleeve accessories, in the future of printing technology.

However, we will start seeing accelerated convergences in graphics services at both the supplier and manufacturing levels. This convergence will result in better services for the end-user as suppliers seek to provide a one-stop service to their customers.

4. Expect more automation in printing

We are living in the age of automation brought about by intuitive applications and software. The same is happening in printing technology and is set to escalate even further. Managing all aspects of a business in real-time is going to define the printing technology sector.

By using an app or software, clients can monitor their printing jobs to understand at what stage they are. This will result in more transparency between the manufacturing facility and the customer. Besides, automation will lead to greater efficiencies and accountability.

5. Continued growth in cold foil and digital foil

Advances in printing technology are fuelling growth in print decorating, especially in metallic finishing. The ability to quickly apply special finishes at a fraction of the cost is informing the changes and growth in digital and cold foil printing. Since the new decorating technologies are just starting to take root, we can expect the trend to continue for the future of printing technology.

Expect to see changes and growth in coating and digital foiling technologies, and in cold foiling as well, especially for sheet-fed folding carton and narrow-web label applications. The demand for metallic finishes will also see a resurgence of the traditional hot foil stamping techniques.

Since it does not require tools, digital foil technology makes it easy to decorate small-run printing projects. Using a metallic foil, one can personalize variable data using both tone and varnish adhesive foiling. This was not possible with either cold or hot foil processes.

6. Digital textiles

Textiles have undergone tremendous change with the development of digital textile printing in the twentieth century. It has impacted our understanding of creation and design of textiles in ways hitherto unfathomable. Combined with advances in dye chemistry and versatile fabrics, digital textiles can be used to print complex images on fabric. The ability to quickly print images featuring millions of colours on fabrics at affordable prices has resulted in the spike in demand for digital textiles. This demand is expected to persist into the future.

The future of printing technology is as bright as ever. With technological advances redefining the future of printing tehnology, the emerging printing technologies will permeate into every aspect of our lives. The resulting convergence with other sectors such as healthcare will redefine people’s lifestyles, and may potentially disrupt industries as we know them today.